- LETTERPRESS COASTERS CRACKED

- LETTERPRESS COASTERS MANUAL

- LETTERPRESS COASTERS REGISTRATION

- LETTERPRESS COASTERS CRACK

Coaster stock (blotter) is good because it does the job and is cheap. I do think your idea to use die-cut letterpress stock, like #220 thickness, is a good one- but you may end up spending an arm and a leg.

LETTERPRESS COASTERS CRACK

I suggest you look into the impression strength you’re using on this type of stock, and try to be more careful about how much pressure you apply- back it off a bit and you’ll likely still see and feel the impression, but not crack the blanks.

LETTERPRESS COASTERS CRACKED

Recently I printed some coasters on Katz’s stock on my C&P, and I experienced the cracking as well under deep impression- the client kept asking me to add sheets of tympan until it eventually was about to bottom out, and the last one I was comfortable printing without thinking about my poor press was the one that cracked the coaster.īut fortunately, I backed the impression off just a bit and it went right away, without a noticeable difference in the actual bite depth. Try to fold a coaster and you’ll see what I mean. Coasters for Lesa & Embla Letterpress printed in a three colour halftone / four Pantone spot colours on Beer Matt Board 390gsm and custom die cut. ….when you put the three of those things together, you end up with a brittle stock that will crack. Unfortunately, though, what you’re asking the paper to do is be thick, absorbant, and stiff…… The sheets are really inexpensive for the thickness and it’s the right stock for coasters.

LETTERPRESS COASTERS MANUAL

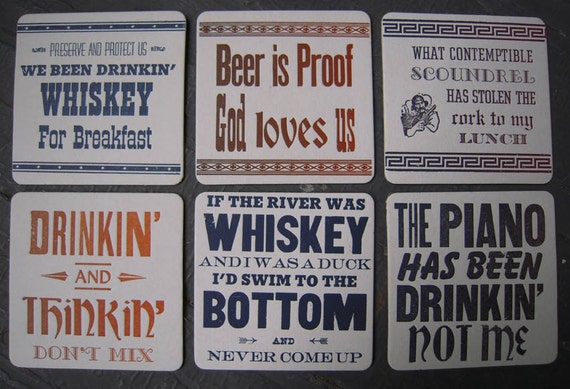

Metal letters and ornaments for manual typesetting.Um, you can get some neenah blotter and then have it die cut. Wooden letters and numbers used for manual typesetting in classic letterpress. To create this set of coasters we fired up our 100 year old Chandler & Price printing press. We were enamored with the contrast between the white snow and dark trees. Metal plates used to make broadsides designed Big Wheel Press. The design for these coaster was inspired by night hiking through the snowy forest.

Once complete, coasters will be die cut on the Heidelberg.

LETTERPRESS COASTERS REGISTRATION

Countless tests may be performed before perfect registration is achieved, but once it is, thousands of perfectly registered pieces can be printed seamlessly on a Heidelberg. The feeder uses suction to grip and rotate the paper from feeding, to print, to placement on the other side, each color requiring a separate pass.Įxamining a test print. Letterpress ink is mixed by hand to specific Pantone colors. Though manufactured over a half century ago, Windmills are still widely acclaimed for their versatility, reliability, speed, and precise registration.Ī polymer plate, more commonly used over wooden and metal plates in modern day letterpress printing. The Heidelberg Windmill, a German-built, world renowned press with a name derived from its sweeping windmill feeder. We use a digital 4-color, high-resolution press for fine detail and rich color. Though pictures can’t capture some of the best things we observed – the precision of setup, the smell of the ink, the feel of the perfect impression – we did get snapshots of lots of other amazing things. Each coaster is carefully die-cut in a letterpress, which gives the top edge its distinctive rounded shoulder. In today’s high-speed, high-tech, digital world, this was an opportunity to take a step back, unwind, and appreciate letterpress for what it is – a process so meticulous, unpretentious, and timelessly exquisite it is nothing less than an art.īelow is a photo outline of our experience at Big Wheel Press.

With extensive paper knowledge but limited letterpress knowledge, we presumed this would be an opportunity to see presses in action, meet some great people, and learn about letterpress along the way. The course was taught by letterpress expert Peter Fraterdeus and covered the intricacies of producing a dual-sided, dual-color, die cut coaster* using a Heidelberg Windmill.

My colleague and I recently had the pleasure of attending a letterpress master class at Big Wheel Press in Easthampton, Massachusetts.

0 kommentar(er)

0 kommentar(er)